Blenders

Overview

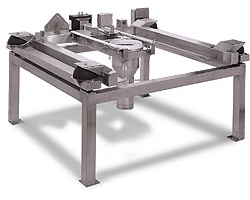

Tote® Blenders are an integral module in the Tote® material handling process. They are unmatched in quality and known for their ability to achieve high blend uniformity in a short period of time. Our idea is clear and effective. The same Tote® container that is used throughout the entire manufacturing process also serves as the blending unit. This eliminates cross contamination, costly product change-over times and blender cleaning and preparation. Tote® Blenders also greatly reduce the potential of segregation by eliminating material transfers from container to blender and back to container.

Standard Features

- Top clamp on double pedestal and bottom clamp on single pedestal

- Safety interlocks including safety gate lockout

- Slow speed start and stop

- Product leveling feature

- Variable blending speed

- Remote operator panel

- Allen Bradley PLC controls

- 2-20 RPM blending speed

- TEFC drive motor

- NEMA 4x electrical enclosures

- Manual/ Maintenance override controls

- Electronic braking on blending motor

- Allen Bradley powerflex variable frequency drive

- All stainless steel surfaces chemically cleaned and passivated

Options

(Available in single or double pedestal design)

- Hydraulic drive and clamping available only on double pedestal configuration

- Pallet jack loading (bottom clamp) or fork lift loading (top clamp) of bin

- Cladding of all open framework

- Complete electrical package to meet NEC area code classifications (Class I or II, Div 1 or 2, etc.) as required

- Stainless steel NEMA 4x electrical enclosures

- Operator interface terminal with recipe controlled blending

- Customer specified PLC’s

- Inverted stop for mid-blend ingredient additions

- Carbon steel or stainless steel construction

PAT Compatible

In November 2001, the FDA introduced PAT (Process Analytical Technology) to ensure that pharmaceutical manufacturers had access to tools and systems that utilize real time measurements, in process, of materials to provide information to determine optimal processing for the production of final products that consistently conform to established quality and performance standards. www.mathisinstruments.com

Need more details about Tote’s® industrial pharmaceutical Blenders? Call us at 888-712-0474 or use our convenient Contact Form and we’ll contact you at your convenience.