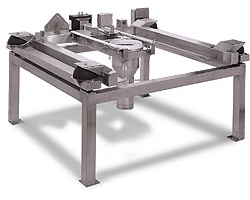

Premier Discharge Stations

Overview

TOTE® Discharge Stations are the foundations for bulk contained product transfer from our containers to destination. These units usually feed equipment such as tablet presses, encapsulators, process vessels, granulators and mills. Many options are available for automation, segregation prevention or metered output.

Standard Features

- Mirror polished “product contact” surfaces

- #4 finish on ”non-product contact” surfaces

- “Product contact” welds ground smooth and flush

- “Non-product contact” welds are as laid and strip buffed

- All stainless steel surfaces chemically cleaned and passivated

- Silicone compression seal

- Safety interlocks

- Remote operator panel to control or indicate all options requested

- Manual/Maintenance override controls

- Stainless steel NEMA 4x electrical enclosures

- 304 stainless steel construction

Options

- Pallet jack or fork lift loading of bin

- Inflatable seals

- 6”, 8”, 10” and 12” seals

- Complete electrical package to meet NEC area code classifications (Class I or II, Div 1 or 2, etc.) as required

- Load cell weighing

- Secondary control panel, local to discharge station

- Deceleration device (pinch rolls) and controls

- Customer specified PLC’s

- Special finishes per customer requirements

- Discharge hopper dust cover, automatic sliding or manual removable cover

- Hopper outlet connections flanged, straight, tri-clover, etc. per customer requirements

- Elevated stands

- Bin valve actuator

- Bin in place sensor

- Product flow sensor

- Electric or pneumatic vibrator with automatic or manual control